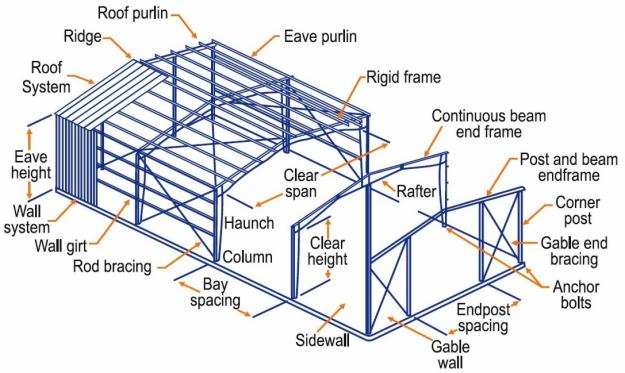

Metal Buildings Framing Systems

American Metal Buildings systems are constructed in many different shapes and sizes for many applications, from manufacturing and distribution centers, retail and commercial facilities, offices and schools, recreation centers and self-storage facilities, to healthcare and correctional institutions. American Buildings Company has the advanced design, engineering, and manufacturing capabilities to be a single-source supplier for a wide range of Metal Buildings systems. American accomplishes this by offering a variety of building styles, framing styles, column shapes, and girt conditions that can collectively satisfy virtually all building requirements.

Building Styles

Building styles offered by American include three common designs. The Gable Style (GS) provides a traditional center ridged-roof slope available in a variety of pitches. The Single-Slope Style (SS) has similar characteristics of the Gable Style but in a single-slope configuration. The Lean-To Style (LS)resembles the Single-Slope but provides an economical means of making a building wider by extending its roof line or it can be attached to a lower level on the building to provide additional office or storage space.

A Gable Roof System (GS) provides a roof with two sloping sides and a ridge. With optional tapered columns, this style of building is a cost-effective solution for office, warehouse, industrial, and commercial applications. The available straight column option provides a good system for palletized storage or display racks and is also ideal for shopping centers and other commercial buildings. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. The Gable Roof System is available with clear span frames or with interior columns, which provide economical solutions for wide buildings.

A Single Slope System (SS) provides a building with one roof surface. With single-side drainage, these systems are suitable for manufacturing facilities, warehouses, and retail shopping centers. The available tapered columns provide an inexpensive solution for wider buildings, while the available straight columns allow for maximum usage of interior space. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. Clear span frames are available or interior columns can be added to provide an economical answer for wide buildings.

A Lean-To System (LS) provides a cost-efficient means of making a building wider by utilizing a single slope system to extend the roof line of a building or by attaching to a lower level on the building. This is ideal when additional space for office or storage is needed.

Column Shapes

Column shapes are determined by several factors, including a building's required roof slope and interior clear spans. American provides two styles of column shapes. The Tapered Column is normally found in buildings where interior finishing is limited, such as warehouses, distribution centers, and storage facilities. The Straight Column allows for interior walls and maximum use of interior space.

Framing Styles

There are two primary framing styles found in American's building systems. The Rigid Frame is the most economical style for clear span and modular widths. It is normally used in buildings where higher center clearance or greater roof slope is desired. The Girder Column Frame offers straight wall columns and inset framed girts. This style offers extreme widths and the lowest roof slope possible.

Girt Conditions

Girt conditions refer to the method in which horizontal girts are attached to the exterior columns in a building. The most common condition, the Bypass Girt, makes a continuous run around the outside of a building’s columns, providing an air space the width of the girt between the column and the exterior panels. An Inset Girt minimizes the air space between the columns and exterior panels. Flush Girts provide no air space between the columns and exterior panels yet offer the maximum amount of floor space.

Metal Buildings Roof Panels

Seam Loc

These architectural standing seam panels are connected with a 1-3/4" high snapped seam and are available in 12", 16", and 18" width coverage. They are designed to be utilized over solid substrates but can also be used over open structural framing. A minimum slope for the Seam Loc roofing panel is 3:12

Long Span III

These roof panels have 1-1/4" ribs on 12" centers for an even-shadowed appearance. They offer 36" width coverage and are reinforced between the ribs for added strength. Panel is available in 26 gauge steel as standard. 22 and 24 gauge can be special ordered.

Loc Seam

Loc-Seam and Loc-Seam 360 standing seam roof panels offer a flat profile for an attractive appearance on higher pitched roofs and are available with 12" or 16" of width coverage with 2" high ribs. Loc-Seam panels have full 360 degree rolled seams formed with an electrical seaming machine.

Standing Seam II/Standing Seam 360

In American standing seam roof systems, the roof floats on a system of sliding clips that prevent damage from thermal expansion and contraction. Standing seam designs also eliminate 80% of the through fasteners found in other systems for greater weathertightness. American Standing Seam ll and Standing Seam 360 panels provide 24" width coverage with 3" high ribs. Standing Seam 360 panels are joined by an electric seaming machine, developing a full 360-degree rolled seam to ensure weathertightness - a seam type preferred by many architects and specifiers.

Metal Buildings Wall Products

American Buildings offers a wide variety of metal wall products as well as industry leading alternate wall products. Their innovative offering provides aesthetic flexibility and design choices for all building types.

Shadow

These 16" net width embossed panels have deep-fluted profiles that accent contrasting shadow patterns. Panels are 3" deep. They are offered in 24 gauge steel and fastened to the framework from the inside leaving no exposed fasteners.

Architectural III

These wall panels provide 36" width coverage with a decorative shadow line and semi-concealed fasteners. Rib height is 1-1/4" on 12" centers; and this panel is provided in 26 gauge steel as standard. 22 and 24 gauge can be special ordered.

Long Span III

These wall panels have 1-1/4" ribs on 12" centers for an even-shadowed appearance. They offer 36" width coverage and are reinforced between the ribs for added strength. Panel is available in 26 gauge steel as standard. 22 and 24 gauge can be special ordered.

Architectural "V" Rib

These wall panels provide 36" of coverage and reveal a sculptured appearance. With semi-concealed fasteners, the panels have a 15/16" high rib and are made of 26 gauge steel.

Insulated Panels

Insulated Panels add aesthetic value and improve energy efficiency with attractive, affordable and easy-to-install insulated panels.

Stucco Choice

Now you can have the fashionable, versatile look of stucco with remarkable ease, affordability, durability, and some of best warranties in the industry.

Fire-Resistive Insulated Panels

Our fire-resistive panel is the latest development in fire resistive wall construction technology. Unlike traditional wall materials, this insulated fire-resistive panel offers a level of flexibility that architects, contractors, and building owners won't find in any other product in the U.S.

Metal Buildings Components